Steam Turbine Blades Repair and Root Cause Analysis: Understanding Why Turbine Blades Fail

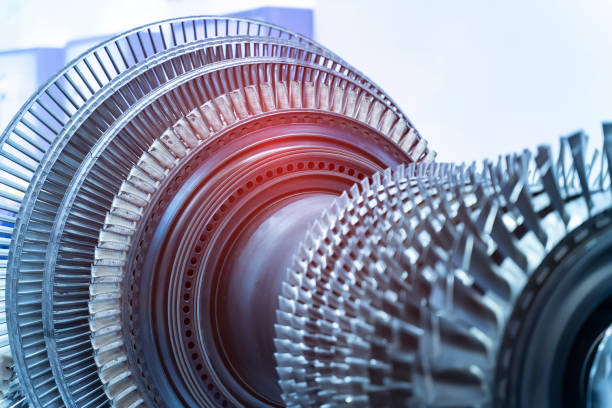

Steam turbines operate under some of the harshest mechanical and thermal conditions in any industrial environment. Inside a turbine, thousands of blades spin at extremely high speeds while being struck continuously by high-temperature, high-pressure steam. These blades extract energy from the steam and convert it into rotational force that drives power generation.

Because of these extreme conditions, turbine blades are also among the most failure-prone components of a steam turbine. When blade damage occurs, it can lead to vibration, efficiency losses, forced outages, and in severe cases, catastrophic equipment damage. That is why steam turbine blades repair must always be guided by thorough root cause analysis—not just surface-level fixes.

Understanding why blades fail is just as important as knowing how to repair them.

Why Root Cause Analysis Is Critical in Steam Turbine Blades Repair

Many plants make the mistake of repairing visible blade damage without addressing the underlying reason it occurred. This leads to repeat failures, rising maintenance costs, and shortened equipment life.

Root cause analysis identifies:

- The mechanical, thermal, or chemical source of the damage

- Whether the failure was operational, material-related, or environmental

- What corrective actions are required to prevent recurrence

When steam turbine blades repair is combined with root cause analysis, plants achieve longer blade life, better performance, and greater reliability.

The Major Causes of Steam Turbine Blade Failure

Although turbine blades are engineered from advanced alloys and designed for long service life, several destructive forces act on them continuously. The most common failure mechanisms include the following.

1. Erosion from Moisture and Particles

One of the most frequent causes of blade damage is erosion. In low-pressure turbine stages, steam often contains moisture droplets and solid particles. As these strike the blades at high velocity, they gradually remove material from blade surfaces.

How erosion affects blades

- Leading edges become thin

- Blade tips wear down

- Aerodynamic profiles degrade

- Surface roughness increases

Erosion reduces the blade’s ability to extract energy efficiently, leading to power losses and imbalance. Without timely steam turbine blades repair, eroded blades can crack or fail completely.

2. Corrosion from Steam Chemistry Issues

Improper water and steam chemistry is another major cause of blade failure. Dissolved oxygen, chlorides, and acidic compounds attack blade materials, especially during startup and shutdown cycles.

Corrosion leads to:

- Pitting

- Stress corrosion cracking

- Material embrittlement

- Loss of fatigue strength

Once corrosion penetrates the blade surface, cracks can propagate under cyclic stress. Steam turbine blades repair often includes corrosion-resistant coatings and surface restoration to prevent recurrence.

3. Fatigue from Cyclic Loading

Steam turbine blades are subjected to millions of stress cycles during normal operation. These stresses come from:

- Rotation

- Steam forces

- Temperature changes

- Start-stop cycles

Over time, microscopic cracks develop and grow until the blade fractures. This type of failure is known as high-cycle or low-cycle fatigue.

Without proper monitoring and inspection, fatigue cracks remain hidden until sudden failure occurs. Root cause analysis helps identify whether operating practices, vibration, or material limitations are responsible.

4. Foreign Object Damage (FOD)

Foreign object damage occurs when debris enters the turbine flow path. This may include:

- Loose insulation

- Bolts or fasteners

- Welding slag

- Corrosion products

When these objects strike turbine blades, they can cause dents, chips, and cracks that compromise structural integrity. Steam turbine blades repair can restore geometry, but preventing FOD requires improved filtration, inspection, and maintenance procedures.

5. Vibration and Resonance Issues

Every turbine blade has a natural vibration frequency. If operating conditions cause a blade to resonate at or near this frequency, destructive vibration occurs.

This can be caused by:

- Improper blade design or repair

- Rotor imbalance

- Steam flow instability

- Changes in operating speed

Resonant vibration leads to rapid fatigue cracking and blade liberation. Root cause analysis during steam turbine blades repair identifies whether frequency tuning, damping, or balancing is required.

6. Manufacturing or Material Defects

Although rare, some blade failures originate from:

- Inclusions in the metal

- Improper heat treatment

- Welding defects

- Poor surface finish

These weaknesses reduce the blade’s ability to withstand stress. Advanced inspection techniques such as ultrasonic testing and metallurgical analysis help identify these hidden flaws before repaired blades are returned to service.

See also: Top Tech Trends to Watch in 2025

How Root Cause Analysis Is Performed

Professional turbine repair facilities use a structured approach to determine why blade damage occurred.

This process includes:

Visual and dimensional inspection

Identifies erosion, cracks, deformation, and wear patterns.

Non-destructive testing (NDT)

Detects subsurface defects using ultrasonic, eddy current, and magnetic particle testing.

Metallurgical analysis

Examines material composition, hardness, and microstructure.

Operational data review

Evaluates vibration history, temperature trends, load cycling, and steam quality.

By combining physical evidence with operating data, engineers determine the true cause of failure before starting steam turbine blades repair.

How Root Cause Analysis Improves Repair Outcomes

Without root cause analysis, a repaired blade may look perfect—but still fail again under the same conditions.

When root causes are addressed:

- Erosion-resistant coatings are applied

- Steam chemistry is corrected

- Blade profiles are optimized

- Vibration problems are eliminated

- Maintenance practices are improved

This turns steam turbine blades repair from a short-term fix into a long-term reliability solution.

Modern Repair Technologies Restore and Improve Blade Performance

Advanced steam turbine blades repair methods allow damaged components to meet or exceed OEM performance standards.

These include:

- Precision welding and laser cladding

- CNC machining to restore aerodynamic profiles

- Tip rebuilding and sealing surface repair

- Protective coatings for erosion and corrosion resistance

- Dynamic balancing after repair

When guided by root cause analysis, these technologies not only restore blades—but also extend their life beyond original expectations.

The Cost of Ignoring Root Causes

Failing to identify why blades fail leads to:

- Repeated outages

- Rising repair costs

- Lost generation revenue

- Higher safety risks

- Premature turbine retirement

In contrast, a root-cause-driven steam turbine blades repair strategy delivers:

- Longer component life

- Improved efficiency

- Reduced downtime

- Lower lifecycle costs

Conclusion

Steam turbine blades do not fail randomly. Every crack, erosion mark, and fracture has a cause rooted in physics, chemistry, or operation. By combining professional steam turbine blades repair with detailed root cause analysis, power plants can break the cycle of repeat failures and move toward true asset optimization.

Understanding why turbine blades fail is the key to keeping them running—safely, efficiently, and reliably—for years to come.